Products

Sheetfed Ink

Premium quality sheetfed Offset process printing ink

| Outline | Features |

|---|---|

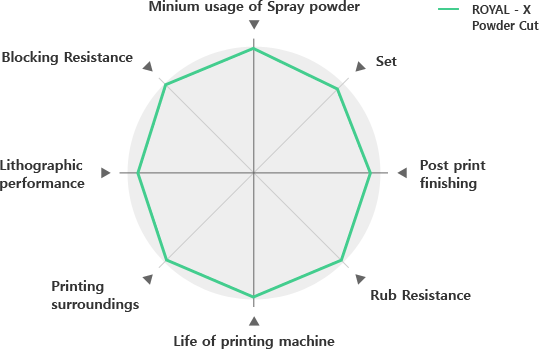

| "ROYAL-X Powder Cut Sheetfed ink" is the next generation process ink that can reduce the amount of spray powder used at actual sheetfed printing. The spray powder which is basic material for sheetfed printing, has been used to prevent the set-off of sheetfed printing over the last 60 -70 years. But in the middle of printing, the spray powder could be one of variables to make printing trouble, especially post printing job as lamination process is done. The recently developed , Royal X- Powder cut 4 color has been developed using high functional resin , varnish , special beads. It features excellent rub resistance and blocking resistance and minimizes the spray powder as well. |

|

| 0(bad) - 10(good) | 0 5 10 |

|---|---|

| Minium usage of Spray powder | 10 |

| Set | 9 |

| Post print finishing | 9 |

| Rub Resistance | 10 |

| Life of printing machine | 10 |

| Printing surroundings | 10 |

| Lithographic performance | 9 |

| Blocking Resistance | 10 |

| Product name | Color | Type | Features | Packing |

|---|---|---|---|---|

| ROYAL-X Powder Cut | YELLOW |

H type N type S type |

Premium quality Gloss-Coated Paper Sheet-fed Offset Art paper |

1kg tin 12 cans in a box 1kg vacuum 2.5kg vacuum |

| MAGENTA | ||||

| CYAN | ||||

| BLACK |

H Hard N Normal S Soft

Scroll right to see more tables.

RESISTANCE

| Lightfastness | Alcohol resistance | Alkaline resistance | Foil Lamination Ability | UV Varnish Ability | Aqueous Coating Ability | |

|---|---|---|---|---|---|---|

| YELLOW | 5 | + | + | +/(-) | +/(-) | + |

| MAGENTA | 5 | + | - | +/(-) | +/(-) | -(*) |

| CYAN | 8 | + | + | +/(-) | +/(-) | + |

| BLACK | 8 | + | + | +/(-) | +/(-) | + |

Scroll right to see more tables.

* Due to potential colour shift, it is advised that test prints are made before starting a production run

+/(-) Mostly Resist but it is recommended that the pre-test should be proceeded.

STORAGE AND PACKING

Only store the ink in a specified place at ambient temperature – ideally the temperature range should be 18 -25 ‘C.

1kg vacuum tin / 12 cans in a box

2kg catridge / 6 cans in a box

2.5kg vacuum tin / 4 cans in a box

200kg barrels

SAFETY, HEALTH AND ENVIRONMENTAL REGULATIONS

KMI inks are formulated based on EU regulations, EU REACH and for detailed information, please refer to recent GHS MSDS.

This data sheet is for information and reference when using KMI inks. It is correct to the best of KMI’s knowledge. No liability for any errors, facts or opinions is accepted. Customers must satisfy themselves as to the suitability of this product for their application. During application, performance of the product can be affected by various factors which are beyond the control of KMI, so it is highly recommended that a test print is made before committing to a production run. The information contained herein may be modified without prior notice.