Products

Newspaper Ink

Versatile Newspaper ink

| Outline | Features |

|---|---|

| In order to cope with high-speed printing, factory automation, and cost saving production, we have applied a new concept of utilizing a high performance resin and high quality pigment. This reduces paper loss for print start up and maintain stable workability while long run printing. It guarantees the best quality under all types of printing conditions and maintain the optimum printability and stability. It is high quality offset coldset ink that has excellent ink transferability, halftone dot reproducibility, and ink mileage. |

|

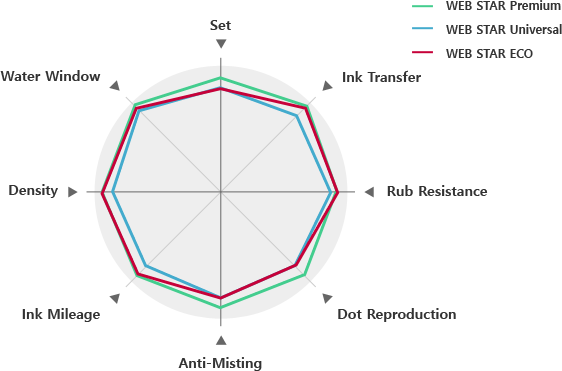

| 0(bad) - 10(good) | 0 5 10 |

|---|---|

| Density | 7 |

| Ink Mileage | 8 |

| Anti-Misting | 7 |

| Dot Reproduction | 7 |

| Rub Resistance | 8 |

| Ink Transfer | 8 |

| Set | 8 |

| Water Window | 9 |

| Product name | Color | Type | Features | Packing |

|---|---|---|---|---|

| WEB STAR UNIVERSAL | YELLOW |

HV(High Viscosity) MV(Middle Viscosity) LV(Low Viscosity) |

High Quality Excellent Printablilty Wide Warter Window |

5kg Square tin 15/20kg Pail Can 200kg in a drum 1Ton Bag |

| MAGENTA | ||||

| CYAN | ||||

| BLACK |

Scroll right to see more tables.

STORAGE AND PACKING

Only store the ink in a specified place at ambient temperature – ideally the temperature range should be 18 -25 ‘C.

5kg Can / 20kg Pail / 200kg Drum / 900kg Conicube / 1,000kg Fluid

SAFETY, HEALTH AND ENVIRONMENTAL REGULATIONS

KMI inks are formulated based on EU regulations, EU REACH and for detailed information, please refer to recent GHS MSDS.

This data sheet is for information and reference when using KMI inks. It is correct to the best of KMI’s knowledge. No liability for any errors, facts or opinions is accepted. Customers must satisfy themselves as to the suitability of this product for their application. During application, performance of the product can be affected by various factors which are beyond the control of KMI, so it is highly recommended that a test print is made before committing to a production run. The information contained herein may be modified without prior notice.